Fort Vale has introduced two new valves for the tank container industry.

The PFA-Lined Cleanlift, bottom discharge valve has a shear groove that protects the tank in the case of an impact or incident, and complies with EN 14433:2014. The shear groove is a significant feature of these types of valve, but is not universally available from all companies.

Ideally suited for tank containers where space is limited in the ISO frame, with the PFA lining offering maximum protection against highly corrosive cargos, it’s simple to maintain and uses many of the components to be found on our standard footvalves – making spare parts supply easier.

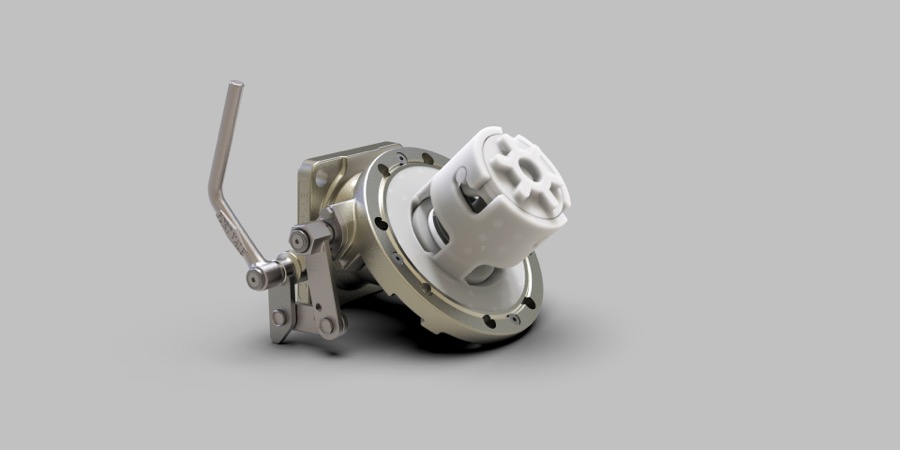

The Drybulk relief valve is designed for use on ISO drybulk tank containers – and is designed to assist contractors who regularly transport flour, cement or indeed any powdered product – design of this valve was encouraged by existing clients in the Southern hemisphere who wanted to combat some of the problems encountered in their geographical region.

Carefully manufactured in stainless steel for maximum corrosion resistance, the Drybulk relief valve will ensure that your products will flow out of your tank container as easily as they flowed in. Like all Fort Vale valves, it’s easy to maintain and service, with spare parts available globally through the Fort Vale offices and distribution network.

Fort Vale’s Graham Blanchard said: “Both these products illustrate that we are always listening to our clients. We are able to design, test and produce equipment on a bespoke basis to help them with the problems they face.

“Successful and profitable tank operation relies upon the technical integrity of each and every component. That’s why we ensure precision throughout, so that you can rely on the performance of our valves and your tanks.”