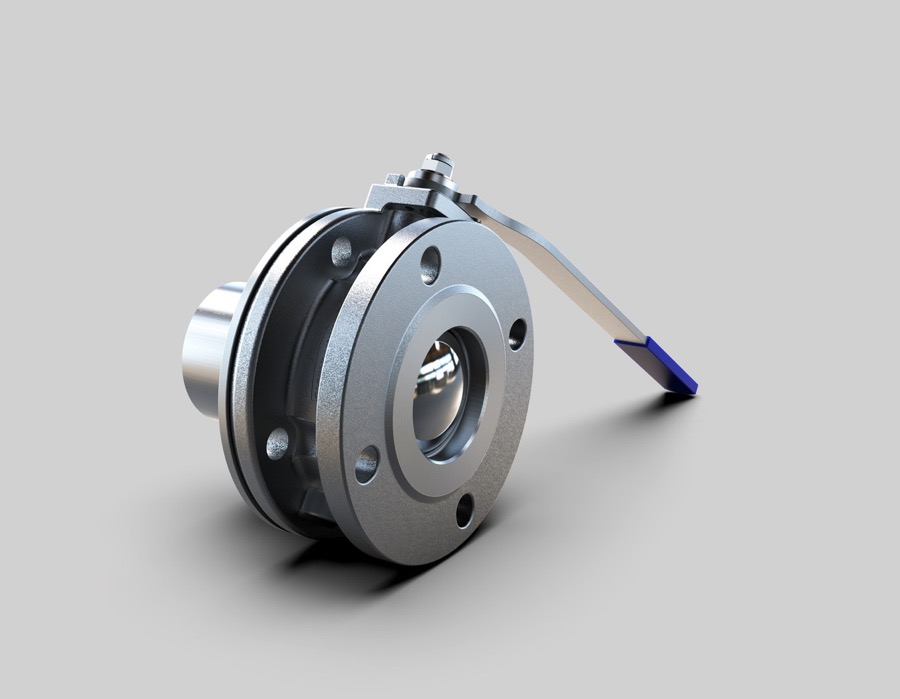

Compact, lightweight and slimmer than existing ball valves by 30mm, the new valve allows customers to use a DN80 connection for loading or unloading on top of a tank container where space is limited. It is precisely for these situations that this valve has been developed.

Made with 316 Stainless Steel for maximum corrosion resistance, the new design offers a reduction in height of the overall assembly – when compared with standard DN80 ball valves – of approximately 30mm due to the cleverly integrated syphon tube and seal carrier design.

The contained seal design improves sealing performance which can be affected by uneven loads when connecting heavy hoses and pipework.

Instead of operators being forced to use smaller equipment in order to work within the restrictions of the fixed tank container size, the DN80 ball valve allows for a flow of maximum capacity – even at its reduced height – thus allowing for unloading without impediment or loss of time.

Andrew Paterson, technical sales account manager at Fort Vale, said: “We have been aware of this operational restriction for some years now and are proud that we have found a simple, workable solution to the problem. It goes to the heart of what we do at Fort Vale – same quality, same performance – but small enough to make a big difference, problem solved.”

For further information visit www.fortvale.com