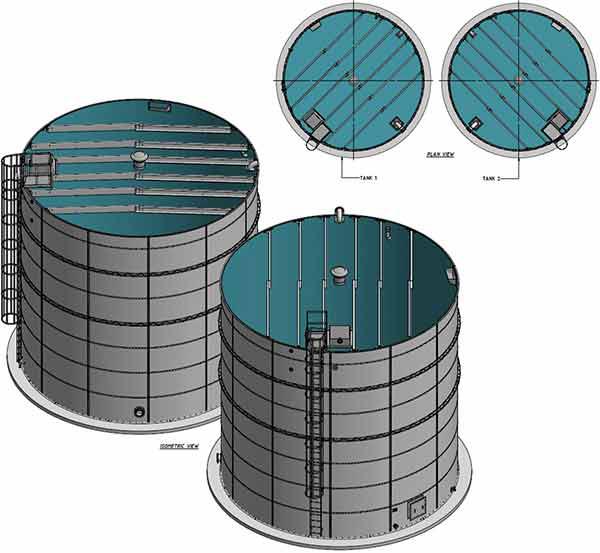

The design team at Balmoral Tanks has recently made the switch from 2D-based drawings to building information modelling (BIM)-ready 3D drawings.

To eliminate costly errors, BIM models are now presented to the client, with traditional engineering drawings and the 3D models used throughout the project to develop the planning and execution of the build. For example, a cylindrical tank 3D model can be dropped into clients’ designs, which facilitates visual checks for clashes.

This concept is known as ‘digital twinning’ – it’s an accurate virtual representation of an object, which can be used to plan, predict, monitor and analyse products or process data. It’s performed using a 3D ‘master model’ that offers several benefits for both internal and external customers. This novel process allows for a 75 percent decrease in initial design time.

Installation teams will also benefit from the new process as communication is shared more visually than before. The new process distinguishes Balmoral in the market by significantly reducing the time required to complete a first issue drawing without sacrificing quality. The 3D models are intelligently designed in CAD software to allow for rapid and easy modification to a client’s specific needs.

As the industry adapts to virtual meetings, Balmoral now uses video sharing platforms to discuss projects with clients and make changes on the fly, sharing live visual information on how the product will look. The system provides scope for instant client feedback. This reduces the number of revisions needed, giving the client the solution they need in less time.

For more information visit www.balmoraltanks.com